The critical role of fasteners in automotive assembly

Threaded fasteners include factors like wellbeing, execution, and strength that are vital in car get together activities, and they not entirely settled by picking the right threaded fasteners . In this article, you will be educated on the different kinds regarding clasp existent available and how to pick the most fitting one for you. In auto mobile industries fasteners are used to joining different parts such as body section and fenders or engine parts.

Proper choice of fasteners is critical in the construction of a car and its safety during the time of operation. Auto industry uses fasteners based on the stress level, load, and the environment they are likely to be used for in an automobile. Performance characteristics include material of construction, shape and type of thread, form of head and style of driving.

Knowledge of these factors is important to automotive engineer, mechanics and purchasing managers when deciding on the appropriate type of fastener. Choosing the correct fastener for a specific task increases assembly capacity, decreases maintenance, and increases vehicle dependability. There are quite a number and variety of threaded fasteners used in the automobile industry that is covered in the following sections as we consider the various types, their material, the design, and specific uses to enable the readers make the right choices when using these threaded fasteners.

Kinds of threaded fasteners and their uses

The toughness and endurance of threaded fasteners are two primary features that determine the efficiency and stability of automotive structures. Some of the most popular are bolts, nuts, and screws, which have been made for use depending on certain objectives. Bolt is a kind of screwing fasteners that are mostly used hand with nut in order to attach one or several parts. They are available in various head types for easy use; hex heads for instance, are ideal for use with wrench or sockets.

Nuts are secured to parts by bolts and are types of internal fasteners. They are available in different dimensions with differences in security and load distribution such as hex nuts, lock nuts and flange nuts. Screws, on the other hand, are External thread fasteners That may or may not require nuts.

Machine screws and wood screws are widely used types of screws in vehicles and they are not the same. Machine screws are of a flat point, self-tapping and are threaded with a straight profile. They are especially useful in metals and are available in several thread densities so as to meet specific material and load responses. On the other hand, the wood screws have more pronounced threaded portions than the standard ones, and a cone-shaped shaft that effectively holds wood materials in place without attending to their fissile properties.

The other class of fasteners applied in automotive assembly is self-tapping screws. These screws are self tapping screws The ‘self tapping’ often refers to the capability of the screw to form its own threads in materials into which it is being used, and they are mostly used in joining thin metals and plastic. Holding force that they can generate and minimal time that would be used in installing them makes them suitable to be used in many automotive manufacturing processes.

British Wheels and automotive accessories consist of specialized fasteners such as wheel studs and lug nuts that are very vital for connecting wheels to vehicles. At this factor it can easily be seen that, the wheel studs are more easier and convenient than the wheel bolts in terms of wheel mounting and wheel replacement. It is crucial to discuss some of the particular uses and benefits of each kind of threaded fastener in order to comprehensively select the ideal auto part for the job.

The automobile industry makes heavy use of fasteners, and a little information about certain materials is important.

The material, therefore has to be carefully chosen, because it determines the strength, reliability of fasteners and their ability to withstand a number of conditions found in automotive environments. There are several types of materials popular among car fasteners producers; those are iron, aluminum alloy, and copper. In particular, each of these metals has distinct characteristics that enable it to be used in a certain capacity.

Bolt, that are made of iron alloys, are universal fasteners because they are very strong and relatively inexpensive. They can be further treated of coated to improve on the corrosion resistance of the metal. On the local level, aluminum alloy fasteners find use in situations where weight is an important consideration since Fasteners made out of it are relatively strong but lightweight.

Copper fasteners are comparatively rare, but they are applied in environments where electrical conductivity and resistance to corrosion are critical. In specific high performance applications, titanium bolts are sometimes used because of their high strength to weight ratio and non corrosive nature.

Recent usage of plastic fasteners indicates that most are made from vinyl and are common in automobile industry. It includes properties like anti-corrosiveness, anti-UV, electrical insulation properties, which is perfect for both internal and external part in automobiles.

Chronological thread types and their resulting performance

Geometry of the thread has a significant impact on the performance of a fastener and its applications. There are two important characteristics of thread: pitch, and whether the thread is coarse or fine.

Thread pitch is the measurement between two consecutive thread crests and is a most significant feature in estimating the holding capacity and performance of a fastener under the condition of vibration. Pitch diameter that refers to the hypothetical cylinder passing through the thread profile is very critical in the classification of the thread fit class and the ability of the fastener to take load and/or vibrations.

Coarse threads and fine threads have certain benefits to them. Fine thread fasteners are normally stronger than coarse thread fasteners of the same nominal size. Nonetheless, the coarse thread fasteners perform much better in terms of pull-out in thin gauge metal applications because of the ‘clamping’ effect.

In car production functional aspects mean that standard sizes of threads are applied to guarantee the compatibility of the components and the convenience in their joining. Typical SAE thread size are 1/4 ”-20, 5/16”-18, 3/8”-16 and 7/16 ”-14 in the case of non – metric size while normally adopted metric sizes are 6mm x 1.0, 8mm x 1.25 and 10mm x 1.25.

Head styles and drive types

Different head style and drive type of a fastener have considerable effect on its better installation and removal from automobiles apart from general performance. Spherically produced heads consist of flat head, round head, pan head and hex head; each of these designed for certain purposes and loads.

There is slotted, Phillips, hex and Torx driving scar, and these determine the ease with which one can fix it and the amount of force that can be applied. Slotted drives are little and adorable but a bit tricky to work with and Phillips drives are a bit tricky during the time of installation. Square recess drives are proving very popular because of this cam-out resistance.

Armored fasteners in particular the TORX PLUS® system has several features that make it ideal for automotive use. Enhancements made to assembly line; increased product quality; and lowered assembly expenses are other benefits given. The Torx design also reduces chances of tool slide off and Negative effects on The fastener or adjacent surfaces.

Effective methods in the use of threaded fasteners

Correct application and management of threaded fasteners is essential in appropriately enhancing their functionality as well as their durability in a car. It is necessary to apply accurate torque while fastener installation is one of the essential procedures of installation. It is recommended that each fastener be tightly clamped at a rate of the specified torque wrench.

Nylons or a thread-locking material for example has been cited as improving the performances of fasteners through elimination of loosening forces like operation vibration. Facil’s offering of threaded fasteners comprises options with diverse locking systems that correspond to the utilization of the automobile industry.

Therefore, in selecting and installing fasteners, some of the important aspects to consider include, choice of material, the environment the fastener is to be used in or placed and more Crucially, load condition. Correct selection of fastener, and adherence to correct installation procedures will help achieve and sustain the required standards of safety, durability, and performance of automotive assemblies.

Accessorizing Cargo Pants

Cargo pants are very versatile and foundational wardrobe pieces. You can dress them comfortably and functionally and make accessories into different outfit styles.

Here, you will learn how to enhance your look by attaching accessories that complement your cargo pants perfectly.

Short History of Cargo Pants

This type of trousers was invented during the 1930s when the British Army required soldiers to wear functional trousers. The added functionality of large pockets allowed soldiers to prepare for their flights more. To this day, they remain fashionable because they are comfortable and stylish.

Benefits of Cargo Pants

- Comfort: Cargo pants are primarily designed using lightweight, breathable materials; this makes them comfortable all day long.

- Practical Storage: With multiple pockets, cargo pants enable practical storage, making them an excellent piece of cloth for those on the go.

- Versatility: Cargo pants come in a variety of styles, colors, and sizes, making them suitable for several fashion trends and occasions.

Pairing Cargo Pants with Perfect Accessories

Footwear

Indeed, it is footwear that can redeem you of your appearance. Below are some recommendations:

-

- Sneakers: These are ideal for wearing when you desire a casual but also fashion-forward style and want to be edgy or rugged.

- Sandals: Best for the carefree summer look.

- Boots: They can be combat boots or ankle boots that provide an edge and a rugged look to your cargo pants.

Bags and Purse

Choosing a good bag will complement your overall outfit. Consider:

- Backpack: Very ideal for the sporty, practical look.

- Crossbody Purse: Pretty great to use hands-free

- Tote Bag: Perfect for a full day in an event or office setting.

Jewelry

To give that little taste to your dress, you can have

- Statement Necklaces: It includes a bold necklace that is perfect if you want some fantastic taste in the look.

- Multi-Strand Bracelets: Stackle bracelets are perfect for some nice texture and personality.

- Dainty Ear Studs: These are perfect when you want to make quite a bold statement.

Watch

Cargo pants are classy and perfect with a well-styled watch for men, made available in various designs and materials. You can opt for any of the below:

- Casual Watches: These are very simple in design, durable materials, and versatile colors for casual use.

- Sporty Watches: These are suitable for a sporty look, as they are water resistant and have a stopwatch function.

- Dress Watches: They have a sleek, minimalist design and are worn when you must dress up and go out at night.

If you are searching for excellence and looking, visit the Seiko Philippines. Seiko has been famous for its craftsmanship and innovative designs that perfect functionality and elegance for years. These are great companions to complement cargo pants with other pieces of clothing.

Outfit Ideas for Any Occasion

Casual Outings

Cargo pants with sneakers paired with a graphic tee and denim, keeping it classy by wearing fashionable accessories.

Work or Business Casual

Cargo pants are fitted using a blouse or coat, loafers, a structured bag, and a watch for a more refined look for business purposes.

Evening Events

One can dress cargo pants into heels, fitted tops, and bold accessories.

Weekend Escapades

Athleisure looks relatively straightforward for boys wearing cargo pants, sporty shoes, a backpack, and a Seiko 5 Sports watch, known for its durability and sporty design.

Wrapping Up

Cargo pants are suitable for many occasions. Dress yourself up with them, especially a fashionable watch, and you’ll never have to worry about how you will dress up anymore. Test your style and experiment with accessories. Upload pictures of your favorite accessorized cargo pants on social media and enjoy the freedom of styling!

The Functioning of Airless Dispensing Systems

Use of airless dispensing systems has increases in the personal and health care, pharmaceutical, and cosmetic industries. These innovative plastics make it easy to use the product, extend its shelf life, and protect food.

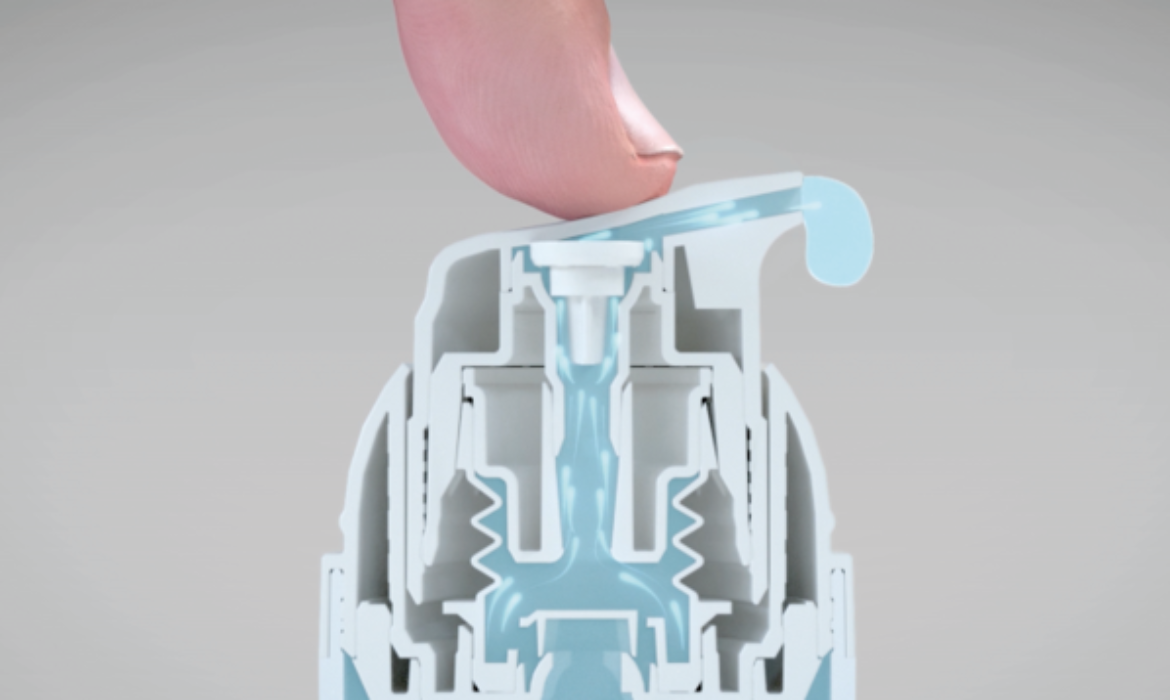

- The Fundamental Design of Airless Dispensing Equipment

Generally, airless dispensing machines consist of three primary parts:

Container: This holds the product and is often constructed from materials that shield the formulation from deterioration by light and air

Pump Mechanism: An innovative pump design that evenly distributes the product without adding air.

Actuator: The component that the user pushes or presses to let go of the item.

-

How They Operate

Mechanism of Vacuum

A vacuum mechanism is used by airless dispensing systems to dispense the product. This is how it operates:

Sealed Environment: After the product is poured, air cannot enter the container because it is made to be airtight. Pollution and oxidation are reduced in this setting.

Pushing Mechanism: The pump mechanism presses down on a piston or diaphragm within the container when the actuator is pressed. The product is drawn upward through a small tube and towards the actuator by the vacuum created by this motion.

Controlled Dispensing: The product is dispensed in a controlled way that permits accurate application without waste as long as the user keeps pressing the actuator.

Avoiding Air Exposure

The product is never exposed to air, so there is a far lower chance of contamination. This is particularly crucial for formulations that are delicate, including those that contain active chemicals that can break down.

-

Sorts of Airless Infusion Equipment

There are several varieties of airless dispensing devices, each designed for a specific use case:

Bottles: Used frequently for serums, lotions, and creams.

Pumps: Made for liquid goods like gels or makeup in a fluid form.

Jars: Frequently utilised for heavier goods like rich creams or balms.

-

Benefits of Airless Infusion Equipment

-

Integrity of the Product

Airless dispensing device help maintain the effectiveness of active compounds by preventing air exposure, guaranteeing that customers receive the product as intended.

-

Safety and Hygiene

Since users do not need to touch the product inside the container, these devices reduce the possibility of contamination. Bacteria and other pollutants are kept at bay by the sealed environment.

-

Accuracy and Management

It is possible to precisely control the amount with airless dispensing.

-

Longer Shelf Life

With reduced oxidation and contamination, items in airless dispensing devices often have a longer shelf life compared to standard containers.

-

Utilisation in Diverse Sectors

Airless dispensing equipment is frequently utilised in:

Cosmetics: For lotions, serums, and creams when the stability of the ingredients is essential.

Pharmaceuticals: To administer delicate drugs that need to be shielded from light and air.

Skincare: In items like anti-aging formulas that are intended to have long-term effectiveness.

In summary

Dispensing machines without air are a major development in packaging technology, providing a host of advantages that improve user experience and product performance. These devices are favoured in a variety of industries because they assist preserve the integrity and efficacy of sensitive formulations by limiting air exposure and contamination. As long as customers continue to expect quality and safety, as it develops, airless dispensing technology is probably going to be used in product packaging even more.