Introduction

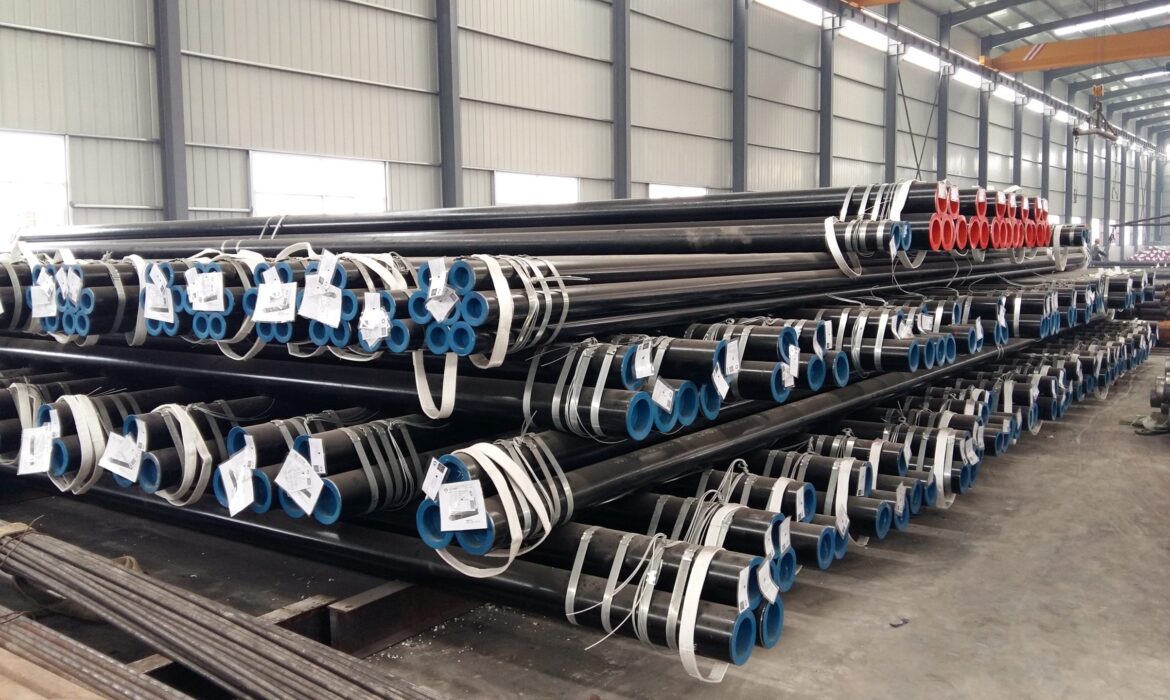

When deciding on the proper substances for piping structures, the controversy between cast iron pipe vs carbon steel pipe regularly arises. Carbon steel pipes have carved out a large area of interest because of their strength, sturdiness, and flexibility. But what precisely are the specific kinds of carbon steel pipes, and where are they used? Let’s dive in.

What Are Carbon Steel Pipes?

Carbon metallic pipes are composed of carbon and iron, with the carbon content usually varying from zero, 05% to a couple of. 0%. This blend gives carbon metal its feature strength and sturdiness. These pipes are widely used across industries for transporting fluids, gases, and even solids, depending on the type of pipe.

Types of Carbon Steel Pipes

Carbon steel pipes are available in numerous sorts, every suited to particular applications. Here’s a closer look at the primary kinds:

1. Low Carbon Steel Pipes

Also called moderate steel pipes, these have a carbon content of less than zero, 25%. Low-carbon steel pipes are distinctly soft and pliable, making them smooth to paint with. Carbon steel pipes are affordable and cost-effective. Due to their strength and value are often used in construction to build frames and equipment parts.

Application Areas

Construction: Widely used inside the construction industry for structural support.

Automotive Industry: Parts with cars, bodies, and chassis often use low-carbon metal pipes.

General Engineering: Common in mechanical elements requiring correct weldability and versatility.

2. Medium Carbon Steel Pipes

Medium-carbon steel pipes have a carbon content between 0.25% and 0.60%. They balance strength and flexibility, making them a versatile choice. They are more potent than low-carbon metallic pipes but still provide remarkable pliability.

Application Areas

Construction: Used in load-bearing systems where extra electricity is needed.

Automotive: Ideal for making gears, axles, and crankshafts.

Machinery: Frequently used in elements requiring high tensile energy and moderate flexibility.

3. High Carbon Steel Pipes

High-carbon steel pipes contain more than 0.60% carbon, making them tough and robust. However, they are much less ductile and more brittle, which means they could fracture below excessive strain.

Application Areas

Cutting Tools: Due to their hardness, they’re often used to make cutting gear, which consists of knives and blades.

Railway Tracks: The excessive energy of these pipes makes them ideal for high-stress programs like railway tracks.

Industrial Machinery: High-carbon steel is solid and durable. It’s often used to make tools that wear out quickly, like drill bits and saw blades.

Specialized Carbon Steel Pipes

There are three main carbon steel pipes: low, medium, and high carbon. Beyond these three main types, specialized pipes are also made for specific industries and uses.

1. Alloy Steel Pipes

Alloy steel pipes are carbon steel pipes with added elements like chromium or nickel. These added elements improve corrosion resistance, toughness, and high-temperature strength.

Application Areas

Petrochemical Industry: Used in environments with excessive warmness and strain, consisting of oil refineries.

Power Plants: Ideal for high-temperature packages like steam pipelines.

Aerospace: Used in essential additives that require extraordinary electricity and lightweight residences.

2. Galvanized Steel Pipes

Galvanized metal pipes are carbon metal pipes covered with a zinc layer, providing safety against corrosion.

Application Areas

Water Supply Lines: These are commonly utilized in out-of-door and underground water supply structures.

Fencing: Used in building fences because of their rust resistance.

Scaffolding: Ideal for transient structures exposed to the factors.

Carbon Steel Pipe Applications vs. Cast Iron Pipe

The debate between forged iron and carbon steel pipe regularly centers around their applications. Carbon steel pipes are strong and flexible, perfect for high-stress jobs. Cast iron pipes are durable and quiet, often used for low-stress tasks like sewage and drainage.

1. High-Pressure Applications

Carbon Steel Pipes:

Oil and Gas Industry: This is notably used for transporting oil, gasoline, and other fluids under high stress.

Power Generation: Employed in excessive-stress steam systems due to their heat resistance.

Cast Iron Pipes:

Water Distribution: Often used in municipal water structures because of their capacity to withstand corrosion.

Sewage Systems: Cast iron pipes are strong and can withstand soil movement. Because of their reliability and durability, they’re often used for underground sewage systems.

2. Longevity and Maintenance

Carbon steel pipes, particularly those galvanized or alloyed, have an extended lifespan in excessive-strain environments. Cast iron pipes need less maintenance and last a long time. They’re a good choice when strength is more important than flexibility.

Conclusion

In the end, the versatility of carbon steel pipes makes them a critical factor across numerous industries. Whether evaluating cast iron pipe vs. carbon metal pipe or exploring specialized alternatives, carbon metallic remains a pinnacle in the desire for many applications.

For more excellent, specific records, check out https://uniasen.com/ to discover more than a few first-rate carbon metal piping answers.

Final Thoughts

When deciding on the proper piping cloth, consider your mission’s unique necessities. Carbon steel pipes offer a range of benefits, from flexibility and strength to corrosion resistance, making them a fantastic choice for many programs.

Remember, the fine pipe for your undertaking isn’t always about the cloth by myself; it’s approximately matching the fabric’s houses to the demands of your software.